Data Collection:

A very comprehensive data collection was

performed at construction sites. Took assistance from the site supervisor to

compute data as precise as possible. We

used to go to the site at least 3 times in a week for a period of 4 months.

Since we had our classes as well on the week days, so we taught the site

supervisor to help us measure data in the hours we weren’t available. Being

undergrad students we had 6-7 hours available for project on daily basis

(except for the project day). Since site work is minimum of 8 hours, which at

times exceeds to 10-11 hours (overtime work) and we could only manage 6-7

hours, so the extra hours measurements were taken by the site supervisor on our

behalf, and later we counter checked those measurements using our own activity

analysis. We remained vigilant while collecting data.

The scope of our project includes four

tangible factors, hence the data we acquired touched all four aspects. For the

first factor, ‘level of experience of

labour’ we looked for sites that had labours with various years of working

experience in the specified activities. On construction site there were labours

with a ranging work experience i.e. from a few months to years of experience.

To bring uniformity and reliability in our results, we categorized experience

into parts i.e. 0-5 years, 5-10 years, 10-15 years etc and cases like labour

having experience of 23 years or 30 years were very rare, hence we ignored

those cases.

‘Complexity of a project’

was

our second aspect. To cover this aspect we chose two sites with ‘higher

complexity’ and two sites with lower complexity. To define a project as

complex, we had to go through literature review. The construction process is

always made up of a multitude of interacting parts. Therefore, in simple terms,

this may suggest that construction is generally complex in nature. However, the

dictionary definition adds another interesting property, i.e. `being difficult

to understand or carry out, intricate, involved’. Since not all construction

production processes satisfy this property, it may then be acceptable to

consider it as a meaningful cut-off point that makes a distinction between a

`complex’ construction process and a simple or `non-complex’ one.

Many experts and researchers have defined a complex process in quite a

number of specific ways. Perrow (1965) defined the complexity of a task

as the degree of difficulty of the

search process in performing the task, the amount of thinking time required to solve work-related problems and the body

of knowledge that may provide guidelines for performing the task. Thompson

(1981) considered complexity as the measure of the difficulty of coordinating a production process comprising of

activities that lack uniformity of work.

Malzio et al. (1988) suggested that a complex process is that

which comprises of operations that are innovative

and conducted in an uncertain situation.

Experts consider project complexity in a number of ways. They see a complex project as follows.

1. That having a large number of different systems that need to be put

together and/or that with a

large number of interfaces between elements.

2. When a project involves construction work on a confined site with

access difficulty and requiring

many trades to work in close proximity and at the same time.

3. That with a great deal of intricacy which is difficult to specify

clearly how to achieve a desired goal or how long it would take.

4. That which requires a lot of details about how it should be executed.

5. That which requires efficient coordinating, control and monitoring

from start to finish.

6. That which requires a logical link because a complex project usually

encounters a series of revisions during construction and without

interrelationships between activities it becomes very difficult to successfully

update the programme in the most effective manner.

Keeping in mind all these points, we rated

our four site projects on a complexity scale. For which we used the method of

Likert scale (on a scale of 1 to 5). 1 representing fulfilment of the condition

at a very small extent & 5 representing fulfilment of the condition at a

very high extent. Sites were rated by observing the site and interviewing the

staff.

Fig 3.6 Complexity of a project

Or even cost wise, Gulberg mall is most

costly project, site is least in terms

of cost of project, as well.

Our third factor is ‘temperature’, literature review says that studies on ‘temperature effect on productivity are not

consistent’. We used to note

hourly data of temperature whenever we were working at site. We took data

during winters therefore there weren’t many fluctuations in the temperature.

‘Overtime’

is our fourth factor. Overtime in this research is defined as the hours worked

beyond the typical 40 h scheduled per week or 8 hours of work per week days.

Extended overtime is frequently used to:

·

Meet tight

project targets from owners

·

Make up for

late changes and project delays

·

Attract

skilled labour to a project

Some owners and contractors consider

extended overtime as necessary and required to meet the demands for faster

schedules or to staff their projects. For them, extended overtime is the norm,

their standard approach to projects.

In our case, the numbers of hours

exceeding 8 hours work in a day, is equal to the number of overtime hours. In

our sites, it ranged from 1 hr to 5 hrs.

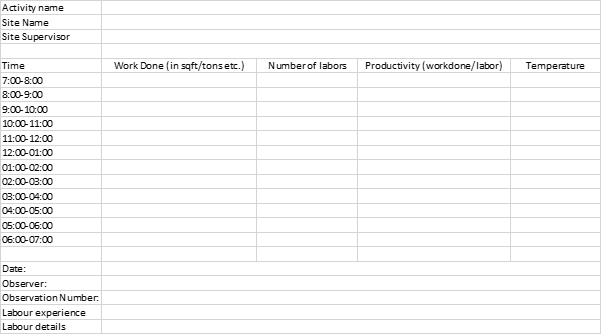

3.4 Process of acquiring data on field with respect to its factors:

3.4.1 Tangible:

Steps:

1.

Reach site,

and see what activities are being performed.

2.

Start

noting data of those activities on the designed site performa, at one hour

intervals.

3.

If you

reach the site late or leaves a bit early, take the assistance of foreman or

site supervisor to fill the remaining hours data. In order to make sure that

data of whole day at construction site is noted in the performa.

4.

Labour

skill level: It was measured by taking readings of labour with a particular

experience. For e.g. one day, work done by labour having experience of 0-5

years, working on a particular activity (let’s say concreting), was measured.

And on another day, work done by labour having experience of 5-10 years,

working on the similar activity (concreting), was measured. Same goes for

labour having experience 10-15 years.

5.

Overtime:

Work done in the hours after 8 working hours was noted as overtime work.

6.

Temperature:

Since we were taking readings at intervals of 1 hour, hence we noted

temperature for 1 hour intervals

7.

Complexity:

Since we rated each project on a complexity scale, so the productivity data for

each site was calculated in hourly average format.

3.4.2 Intangible:

Steps:

1.

Developed a

project management process performa

2.

Interviewing

construction site staff and observing management system

3.

Verifying

our performa results with readings obtained from site

Following is the sample of project management process performa

|

Project Management Process Performa 1.

Site name: 2.

Competency & Number of foreman (years of

experience): 3.

Documentations: 4.

Company SOPs: 5.

Safety Management: 6.

Company SOPs communicated to the administrative body

(till foreman level): 7.

Tools, Techniques & Policies regarding quality

management: 8.

Number of complete projects: |

Fig 3.7 Project management process

performa

No comments:

Post a Comment